Introduction

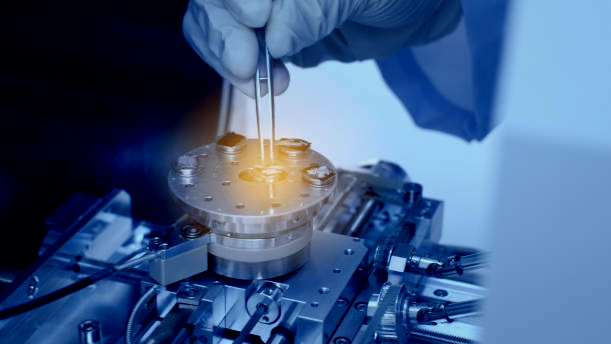

The automotive manufacturing industry relies on precision engineering, high-quality materials, and stringent quality control to produce safe and reliable vehicles. One of the most powerful tools used in this process is the Scanning Electron Microscope (SEM). SEMs provide high-resolution imaging and detailed material analysis at the micro- and nanoscale, making them indispensable for research, development, and quality assurance in automotive production.

Key Applications of SEM in Automotive Manufacturing

1. Material Analysis and Development

Automotive manufacturers continuously seek stronger, lighter, and more durable materials to improve fuel efficiency and performance. SEMs help in:

- Microstructural Examination – Analyzing metal alloys, composites, and polymers to ensure optimal grain structure and mechanical properties.

- Defect Detection – Identifying voids, cracks, or inclusions in materials that could lead to part failure.

- Coatings and Corrosion Resistance – Evaluating protective coatings on components to enhance durability and prevent rust.

2. Failure Analysis and Quality Control

When a component fails, SEMs provide critical insights into the root cause:

- Fracture Analysis – Determining whether a fracture was due to fatigue, stress corrosion, or manufacturing defects.

- Wear and Tear Studies – Examining engine parts, bearings, and gears to understand wear mechanisms and improve longevity.

- Contamination Detection – Identifying foreign particles or impurities that may affect performance.

3. Semiconductor and Electronics Inspection

Modern vehicles contain advanced electronics, sensors, and semiconductor devices. SEMs assist in:

- Microchip Inspection – Ensuring the integrity of solder joints, wire bonds, and circuit pathways.

- Nanoscale Defect Detection – Locating faults in electronic components that could lead to malfunctions.

4. Additive Manufacturing (3D Printing)

As 3D-printed automotive parts become more common, SEMs help:

- Analyzing Layer Bonding – Ensuring proper fusion between printed layers.

- Porosity Assessment – Detecting internal voids that could weaken the structure.

Advantages of SEM in Automotive Manufacturing

- High Resolution – Capable of imaging features as small as a few nanometers.

- Elemental Analysis – Energy-Dispersive X-ray Spectroscopy (EDS) allows for chemical composition mapping.

- Non-Destructive Testing – Samples can often be analyzed without destruction.

Conclusion

The Scanning Electron Microscope is a vital tool in automotive manufacturing, enabling precise material characterization, failure analysis, and quality assurance. By leveraging SEM technology, manufacturers can enhance product reliability, optimize materials, and accelerate innovation in vehicle design and production.

As the automotive industry evolves with new materials and technologies, SEMs will continue to play a crucial role in maintaining high standards of safety and performance.